Posted by on

27/07/2022

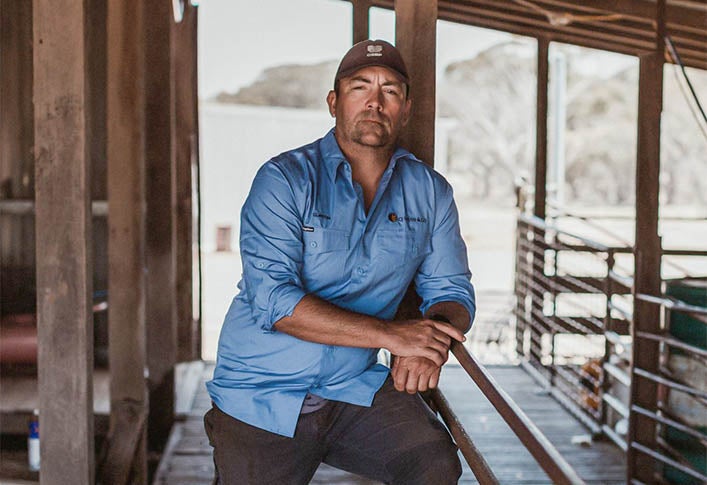

It’s a refreshing ritual enjoyed globally, but for Western Australian barley grower Clayton South, cracking open a cold beer at the end of the day is particularly satisfying.

Thanks to a partnership with Eagle Bay Brewery, barley used in their ‘Wheatbelt Lager’ has been supplied directly from Clayton’s Wagin property for full traceability and, as he describes, “some of our hard work in a can”.

Running a 5,000 hectare mixed farm, consisting of 70 per cent cropping and 30 per cent sheep, Clayton said Eagle Bay Brewery approached the family last year to test the initiative.

“We donated a couple of tonnes of malt barley, had it cleaned at the seed cleaners, sent to the maltsters and delivered directly to the brewery so they could develop ‘Wheatbelt Lager’,” Clayton said.

Eagle Bay had long been inspired by, and had made a commitment to, working towards sourcing ingredients locally and with traceability, to create and maintain a “paddock to pint” product. Originally, Its ‘Wheatbelt Lager’ was intended as a one-off series to launch at one of the region’s signature events, Wagin Woolorama.

And despite the fact Wagin Woolorama was unfortunately cancelled due to Covid at the last minute, the release went ahead and the popularity of the lager soared – prompting Eagle Bay to continue the product permanently in the future.

“It’s a really cool project to be working with Eagle Bay on – as farmers we put so much time and energy ensuring we grow beautiful, quality crops, but once our grain leaves the farm gate we have no idea what happens to it.”

Additionally, Clayton said Eagle Bay could also now capitalise on the consumers’ growing appetite for ‘paddock to plate’ – or in this case, ‘paddock to pint’ experiences.

“Eagle Bay now has an opportunity to tell a genuine story of provenance, and demonstrate that they’re using produce as locally grown as possible. They’re able to put a farming face behind the product, and showcase where their ingredients originated from.”

Clayton and Eagle Bay are currently negotiating the delivery of five to 10 tonnes of barley from this season’s crop to continue the ‘Wheatbelt Lager’ line, and going forward Clayton has the opportunity to supply 200 tonnes annually – which equates to approximately 1,403,508 pints of beer – and can potentially continue increasing his supply annually.

“It’s a really terrific outcome, because at the end of the day we’re a commodity business, and having traditionally sold all our grain through a bulk handler we have no idea where it ends up,” Clayton explained.

“As grain growers, we tend to lose our ‘paddock to plate’ story in the process but this collaboration represents an innovative solution, and we’re really proud to be a part of it.”

And it’s no surprise the ‘Wheatbelt Lager’ has been such a hit, underpinned by a strong local story with a taste Clayton said certainly doesn’t disappoint.

“Eagle Bay has done a fabulous job developing this beer, it’s a plain lager, not as fruity as many craft beers, but one developed specifically with mainstream consumers in mind.”

“At the end of the day the brewer does the bulk of the work, it doesn’t matter how good our grain is, if the beer is no good the whole thing falls over. You can have the best cut of lamb or beef but if it’s not cooked properly it’s pointless, brewing is no different, the brewer is like a master chef, and we have full confidence in Keegan and the team at Eagle Bay.”

Challenges remain, however, and Clayton said additional infrastructure was required to make the partnership work.

“We’re looking at developing a supply chain between the farm, the malting house and Eagle Bay,” he explained. “The malthouse is only capable of handling 50 tonnes at a time, so if we’re going to start supplying large quantities of barley we need to build food standard on-farm storage and deliver grain throughout the year as required, enabling it to be continually malted and delivered to Eagle Bay to be brewed year round.”

Photo Credit: Eagle Bay Brewery

“We’re still trying to nut out some detail, but the specs of our grain are exactly what the brewery needs, so we’re hoping that within the next couple of years Eagle Bay beers will be made using barley grown entirely from our farm.”

A further challenge was ensuring enough in spec grain was produced to meet their commitment, but Clayton said currently the season around Wagin was looking positive – admitting the drier season compared to last year was welcomed.

“Dare we say it, last year was a bit too wet, so we’re looking forward to a good average season. The price of inputs is through the roof, but the price of grain is fairly strong at the moment, so hopefully we can come out with a reasonable result.”

“We want to leave the land in a better condition than when we got it, so our focus is on improving soil carbon through minimum till, stubble retention and strengthening our soil’s structure so it has a better water holding capacity to help utilise available rainfall.”

Shelter belts have also been planted across the property for livestock, and regrowth areas fenced off to encourage biodiversity.

“We’re a conventional farm, and whilst we’re not heading down the organic path, we’re extremely proud of what we produce and how we produce it, whilst aiming to remain profitable. In the cropping industry I’d say most farmers are now adopting best practice techniques and sustainability-based efficiencies, both contributing to the environment, and the business bottom line.”

And now, thanks to the opportunity to supply Eagle Bay, and potentially other brew houses in the future, Clayton can enjoy first-hand the fruits of his labour.

“We do usually have a few beers every week with staff, and it tastes even better when you know all the hard work that’s gone into producing it.”